Showroom

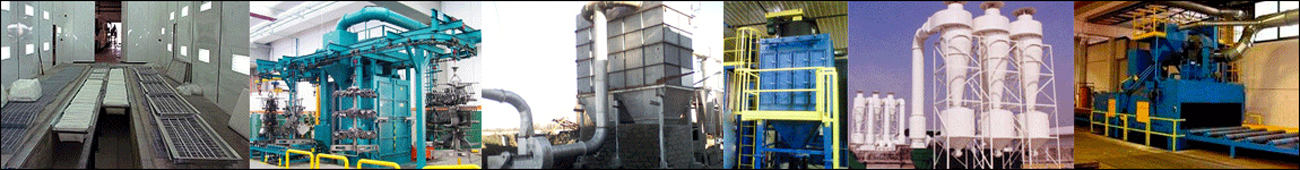

Sand blasting machines are tools utilized for surface preparation by propelling abrasive materials at high velocity onto a surface. They remove paint, rust, and contaminants efficiently. Typically engineered with a blasting chamber, nozzle, and abrasive storage, they provide precise control and versatility. Advantages comprise fast cleaning and adaptability to varied materials.

Shot blasting machines are utilized for surface cleaning, preparation, and finishing by propelling small metallic or non-metallic particles at high speeds. They remove contaminants, rust, and old coatings from surfaces efficiently. Generally designed with a blasting chamber, conveyor system, and blasting wheel, they provide uniform and consistent results.

Table type shot blasting machines are electrically powered automatic devices for surface treatment. Operating at 420 volts with a pressure of 6-7 bars, they efficiently blast surfaces with abrasive particles for cleaning and finishing. Typically painted for durability, they offer automated operation for consistent and effective surface treatment.

Airless spinner hanger shot blasting machines are electrically powered automatic devices for surface treatment, mostly utilized in casting, forging, and sheet metal industries. Their dark blue painted surface guarantees durability. Operating at 420 volts with a pressure of 6-7 bars, they offer uniform and efficient blasting for enhanced surface preparation.

Tunnel type shot blasting machines are kind of electrically powered devices for surface treatment, engineered for casting, forging, and sheet metal industries. Their dark blue painted surface guarantees durability. Operating at 6-7 bars of pressure, they efficiently clean and prepare surfaces. They offer uniform blasting within a tunnel-like structure, enhancing productivity and quality.

The Structure Shot Blasting Machine, painted dark blue for durability, is an electrically powered, automatic device mainly utilized in casting, forging, and sheet metal industries. Operating at 420V and 6-7 bars of pressure, it efficiently cleans and prepares surfaces, enhancing productivity and ensuring high-quality surface treatment.

Rod or Bar Shot Blasting Machines are engineered for surface preparation of cylindrical metal components like rods or bars. Utilizing advanced abrasive blasting techniques, they remove rust, scale, and contaminants, enhancing surface finish and adhesion for coatings. Their design guarantees uniform blasting, offering efficient and high-quality surface treatment for usages in manufacturing and construction industries.

A Cabinet Type Pressure Blaster is a pneumatic-powered, semi-automatic surface treatment device utilized for paint removal. It operates on 415V, three-phase power, with dimensions of 600mm in height, width, and depth. The color is customizable based on customer need, offering efficient paint stripping within a compact enclosure.

The Rod or Bar Shot Blasting Machine is a semi-automatic device designed for surface preparation of cylindrical metal components. With a three-phase power supply of 415V, it efficiently cleans rods or bars, with dimensions of 600mm in height, width, and depth. Its semi-automatic operation ensures ease of use and consistent results.

The Cabinet Type Wet Blasting Machine, powered pneumatically, is semi-automatic and painted for durability. It's used for delicate surface treatments such as deburring, cleaning, and polishing in industries like automotive and aerospace. Abrasive media mixed with water is propelled onto the surface, ensuring gentle yet effective cleaning and finishing.

The Diabola Shot Blasting Machine, powered by electricity, operates automatically with a power supply of 420 volts and 6-7 bars of pressure. Painted for durability, it's utilized for efficient surface treatment, including cleaning and finishing, in various industries. Its technique involves propelling abrasive materials onto surfaces for thorough cleaning and preparation.

The Industrial Shot Peening Machine, semi-automatic, features one blast wheel and a VFD Control Panel for precise control. Equipped with a Pulse Jet Type Auto-Clean Dust Collector, it operates on a power range of 220-440V at a frequency of 50 Hz, efficiently enhancing metal component fatigue resistance through controlled shot peening.